3D Design/Production

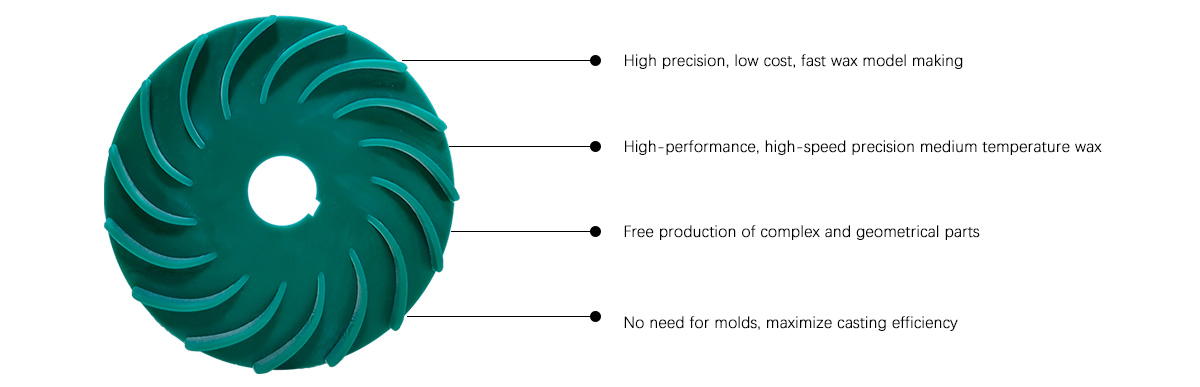

Adopting American new full wax high-precision 3D printing equipment and global 3D molding technology, seamlessly docking with the existing casting workflow, through efficient wax model production solutions, it is ideal for customized metal parts

and small batch production Optionally, a wax casting model can be generated within a few hours. Digital workflow is realized through direct wax model printing, which improves productivity, shortens time to market, and provides customers with high

-quality delivery services.

※ Unparalleled turnaround time The production time of wax model can be shortened by several weeks by using 3D wax model multi nozzle printing without tools. Through direct wax model printing, digital workflow is realized, productivity is improved, product launch time is shortened,and high-quality delivery service is brought to customers. | ※ The cost is only a small part of the cost of mold manufacturing Hundreds of small to medium-sized models you have on hand are faster and cheaper than the time and cost of building and running traditional injection molding tools. If the design needs to be changed, the benefits are doubled. 3D wax pattern can be directly produced on the existing investment casting process and equipment. With this unique 3D printing solution for industrial wax model, you can quickly produce and increase the return on investment. |

※ Ultimate design freedom With digital design, you can generate wax models for parts that leverage topology optimization, lightweight, and component integration. 3D wax printing gives you the freedom to produce parts that are several times the size of the past, or to make design variants at the same time, and it takes only a small part of the time of traditional production methods to provide better performance and more cost-effective components. | ※ Excellent casting reliability 100% wax material has melting and burnout characteristics of standard casting wax. 3D wax printing materials can be seamlessly integrated into the existing wax casting process. With strict tolerance, multi nozzle printing model is an ideal choice for manufacturing complex precision metal components, which can reduce or do not need polishing treatment. |

3D Quick Sample

Unparalleled turnaround time, improve production efficiency, shorten production cycle, and test more design concepts in a short time.

1.TECHNOLOGICAL INNOVATION Complex and difficult surface and functional structure of hand model, can be rapid prototyping and maintain the accuracy principle | 2.PROCESSING SPEED Short production cycle, fast delivery, ensure delivery on time according to delivery date | 3.PRODUCT QUALITY Good quality,guaranteed material, high precision up to 0.02mm-0.1mm |

4.CONFIDENTIALITY SYSTEM Triple security measures to protect proofing | 5.WELL APPOINTED Strong processing function, multiple production lines, advanced equipment, professional and mature supporting facilities | 6.PRICE ADVANTAGE High cost performance, the same level of hand proofing, more affordable price |